Because of its number of uses and longstanding reliability, industrial epoxy is a well-liked choice among manufacturers. This heavy-duty polymer may be used on just about anything, varying from concrete floors to water tanks, costly industrial equipment plus much more. Because of the substance’s naturally sourced qualities, industrial epoxy is both lengthy-lasting and very durable. Its chemical makeup makes up about being able to form firm bonds, permitting the toughest of materials to become became a member of together. Due to this capacity, industrial epoxy is heavily relied upon within the manufacturing world. When offered for industrial use, epoxy is usually shipped in oversized containers, each able to holding vast amounts from the substance, and it is most frequently bought in large quantities by manufacturers.

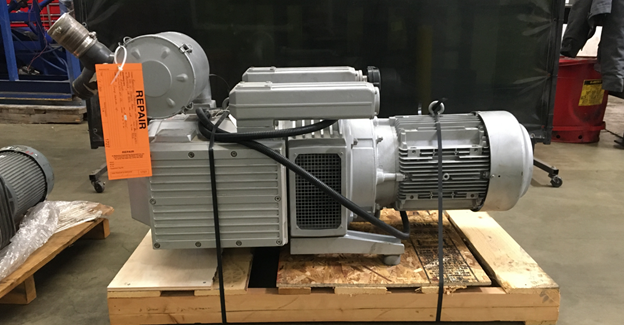

Most manufacturers use costly equipment that’s frequently uncovered to corrosive substances, including water, alkali bases and dangerous chemicals. To protect this equipment from further degeneration, companies depend on various industrial epoxy as a strategy to these complaints. Besides this being substance able to repairing broken industrial equipment, nevertheless its protective polymer coating provides lengthy-lasting prevention against corrosion.

Industrial epoxy can also be utilized as a dependable way of both repairing and looking after concrete floors frequently present in warehouses, manufacturing centers and industrial plants. Given their constant contact with heavy industrial traffic, these concrete floors become spalled and worn with time, which eventually results in the introduction of holes and cracks through the concrete flooring. Manufacturers use industrial epoxy to correct damages, while concurrently resurfacing the floors having a resilient protective coating. This industrial epoxy coating is capable of doing withstanding tough impacts, harsh abrasions and high traffic, together with offering potential to deal with strong chemicals, solvents, cleaners, corrosives and acids.

Water and waste management equipment, including pipes, water tanks, wet wells and basins, can certainly erode because of their constant connection with elements for example brine, mineral acids, alkalis and sewage. To correct current damage while stopping future degeneration, manufacturers apply an anti-corrosive coating to any or all water and waste management equipment. It will not only repair any preexisting corrosion, but it’ll provide lengthy-lasting protection against future damage, despite being confronted with high temperatures, harsh chemicals and abrasive materials.

Overall, the event and employ of these by manufacturers has shown to be successful. Additionally to the plethora of things that you can use it, additionally, it offers protection for the important assets while saving cash over time. With the range of industrial epoxies presently in the marketplace, manufacturers will surely find the correct product to suit their company’s needs. Remarkable ability to correct damage while withstanding harmful substances and two opposites, causes it to be an excellent commodity for manufacturers around the globe.